àªà«àª²àª¿àª¯àª¾àª¥ àªà«àª°à«àª¨à«àª¸

Price 700000 INR/ Number

àªà«àª²àª¿àª¯àª¾àª¥ àªà«àª°à«àª¨à«àª¸ Specification

- વીજ પુરવઠો

- 3 Ph AC

- લિફ્ટિંગ સમય

- મહિનાઓ

- ઇમર્જન્સી સ્ટોપ

- ટ્રોલી યાત્રા ઝડપ

- 20 MPM

- વપરાશ

- Industrial

- રેટેડ લોડિંગ ક્ષમતા

- 1 to 50 Ton

- ઊંચાઈ

- મીટર (એમ)

- ઉત્પાદન પ્રકાર

- Goliath Cranes

- મેક્સ. લિફ્ટિંગ ઊંચાઈ

- મીટર (એમ)

- વજન

- કિલોગ્રામ (કિલો)

- મેક્સ. લિફ્ટિંગ લોડ

- ટન

- લિફ્ટિંગ સ્પીડ

- મી/મીટર

- રંગ

- GOLDEN YELLOW

- લંબાઈ

- મીટર (એમ)

- પહોળાઈ

- મીટર (એમ)

- ગાળો

- 3 to 40 Mtr

- ઓપરેટિંગ મોડ

- Electrical

àªà«àª²àª¿àª¯àª¾àª¥ àªà«àª°à«àª¨à«àª¸ Trade Information

- Minimum Order Quantity

- 1 Number

- ચુકવણી શરતો

- , , ,

- પુરવઠા ક્ષમતા

- દિવસ દીઠ

- ડિલિવરી સમય

- અઠવાડિયું

- મુખ્ય નિકાસ બજાર (ઓ)

- , ,

- મુખ્ય સ્થાનિક બજાર

About àªà«àª²àª¿àª¯àª¾àª¥ àªà«àª°à«àª¨à«àª¸

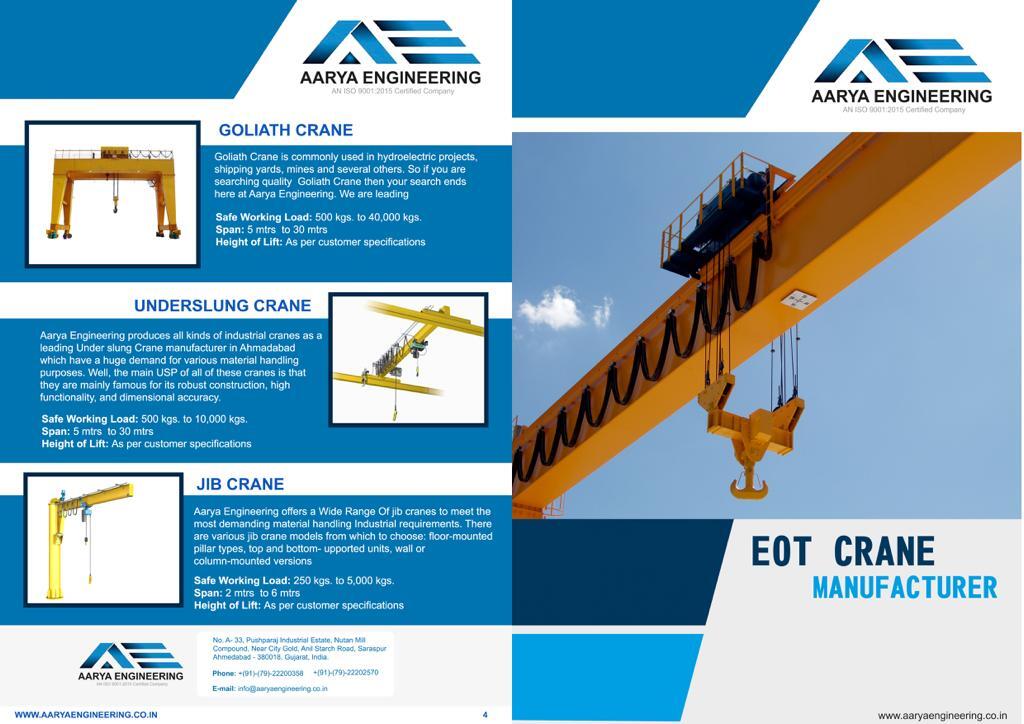

AARYA ENGINEERING are engaged in manufacturing and supplying high quality range of Gantry Crane. which are used for moving loads in different such as up, down, right and left easily. These machines are widely acclaimed for their qualities like high performance and optimum quality. The offered machines are manufactured using premium quality basic raw materials that is procured from our trustworthy vendors of the industry. Further, these Single Girder E.O.T. Cranes are available in various standard and tailored specifications which are offered at the most reasonable prices.

Features:

- Aarya Design cranes have high quality structural assembly,

- Aarya Design cranes have minimum maintenance and emergency interlude

- Easily adjustable limit-switches For All motions.

- Load tested to 125% For Breaking applications.

- Safe and easy to use

- Efficient performance

- Low & Easy Of Maintenance

- Chipper In Cost

- Easy of Installation.

- Low head Room

- Safe & reliable.

Range of Specifications:

- Safe Working Load: 500 kgs to 50,000 kgs

- Span: 3 mtrs to 40 mtrs

- Height of Lift: As per customer specifications

- Class of Duty / Standards: Equivalent to M3,M5, M7, M8 as per IS 3177 / IS 807

- Speeds: Selected depending on client specifications / applications / shed dimensions

- Crane Control: From floor through Pendant Push Buttons, Optionally through Radio Remote Control / cabin with master control

- Drive System: Twin Drive At L Type or Open Reduction Type Wheel through Squirrel Cage 3 Ph. Induction BBl Make Motors with fail to safe Disc / Shoe brakes.

- Motors: Squirrel Cage Induction Motors For All Motion With with built-in fail to safe brakes Disc/ Shoe for Hoisting, Cross Travel as well as Long Travel. Insulation Class for all motors F

- Brakes: Built-in Shoe / Disc Brakes for Hoisting, Cross Travel and Long Travel motions

- Power Supply System: To Hoist and Cross Travel through Trailing Cables By festoon / Drag Chain To Crane through Shrouded Bus Bars (depending on customer's choice and application)

Versatile Industrial Performance

Goliath Cranes are engineered to handle the demanding needs of industrial sectors, offering versatile configurations that support diverse spans, heights, and load capacities. Their rugged construction and reliable operational features make them suitable for factories, warehouses, and large-scale construction sites where efficient material movement is essential.

Advanced Safety and Control

Equipped with emergency stop mechanisms and precise electrical controls, these cranes prioritize both operator safety and effective load management. The integration of variable speeds and sturdy components ensures each lift is secure and seamless, minimizing downtime and optimizing workflow efficiency.

FAQ's of Goliath Cranes:

Q: How are Goliath Cranes typically used in industrial environments?

A: Goliath Cranes are used for lifting and transporting heavy materials across open yards or large factory bays. Their expansive span and robust load capacity make them ideal for moving bulky items, loading and unloading goods, and supporting assembly operations in various industries.Q: What are the main benefits of choosing a Goliath Crane for my facility?

A: Selecting a Goliath Crane offers high lifting capacity, broad operational span, and tailored heights to fit your site requirements. Their electrical operation ensures efficient handling of loads while advanced safety features, such as emergency stops, promote a secure work environment.Q: When should I consider using a Goliath Crane instead of other crane types?

A: A Goliath Crane is recommended when your operations require moving heavy loads over wide areas, especially in outdoor or open factory settings where overhead crane structures may not be feasible. They are also ideal when frequent travel across long distances is necessary.Q: Where are Goliath Cranes commonly installed and operated?

A: These cranes are commonly installed in places like shipyards, fabrication yards, warehouses, and large construction sites throughout India. Their adaptability to both indoor and outdoor setups adds to their widespread industrial use.Q: What is the process for procuring and installing a Goliath Crane?

A: The process begins with assessing your site dimensions, load requirements, and operation modes. You then collaborate with a distributor or manufacturer to customize the crane specifications. After installation planning, the crane is fabricated, delivered, and erected on-site, with operational testing and safety checks conducted before commissioning.Q: How much lifting capacity and height can a Goliath Crane provide?

A: Goliath Cranes can safely lift loads ranging from 1 up to 50 tonnes, with lifting heights from 0 to 40 feet (or up to 20 meters), matching various industrial lifting demands while ensuring operational reliability.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

વધુ Products in ગોલિયાથ ક્રેન Category

ઔદ્યોગિક ગોલિયાથ ક્રેન

ભાવ અથવા ભાવ શ્રેણી : ઇન્ર

ટ્રોલી યાત્રા ઝડપ : 1020 m/min

કિંમતની એકમ : એકમ/એકમો

ગાળો : 1030 meters

રેટેડ લોડિંગ ક્ષમતા : Up to 20 Ton

મેક્સ. લિફ્ટિંગ ઊંચાઈ : ફુટ (ફૂટ)

સિંગલ ગર્ડર સેમી ગોલિયાથ ક્રેન્સ

ભાવ અથવા ભાવ શ્રેણી : ઇન્ર

ટ્રોલી યાત્રા ઝડપ : 05 m/min

કિંમતની એકમ : પીસ/ટુકડાઓ

ગાળો : 1020 m

રેટેડ લોડિંગ ક્ષમતા : Up to 10 Ton

મેક્સ. લિફ્ટિંગ ઊંચાઈ : 612 m

ઔદ્યોગિક ગોલિયાથ ક્રેન

ભાવ અથવા ભાવ શ્રેણી : ઇન્ર

ટ્રોલી યાત્રા ઝડપ : 10 to 20 m/min

કિંમતની એકમ : સેટ/સેટ્સ

ગાળો : 10 m to 50 m (custom built)

રેટેડ લોડિંગ ક્ષમતા : 5 to 200 Tons (customized options available)

મેક્સ. લિફ્ટિંગ ઊંચાઈ : 12 m to 18 m (as per requirement)

ડબલ ગર્ડર ગોલિયાથ ક્રેન

ભાવ અથવા ભાવ શ્રેણી : ઇન્ર

ટ્રોલી યાત્રા ઝડપ : 510 m/min,05 m/min

કિંમતની એકમ : એકમ/એકમો

ગાળો : 3040 m,110 m,1020 m,2030 m

રેટેડ લોડિંગ ક્ષમતા : 60 Ton

મેક્સ. લિફ્ટિંગ ઊંચાઈ : ફુટ (ફૂટ)

|

AARYA ENGINEERING

બધા હકો અમારી પાસે રાખેલા છે.(વાપરવાના નિયમો) ઇન્ફોકોમ નેટવર્ક પ્રાઇવેટ લિમિટેડ . દ્વારા વિકસિત અને સંચાલિત |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese પૂછપરછ મોકલો

પૂછપરછ મોકલો