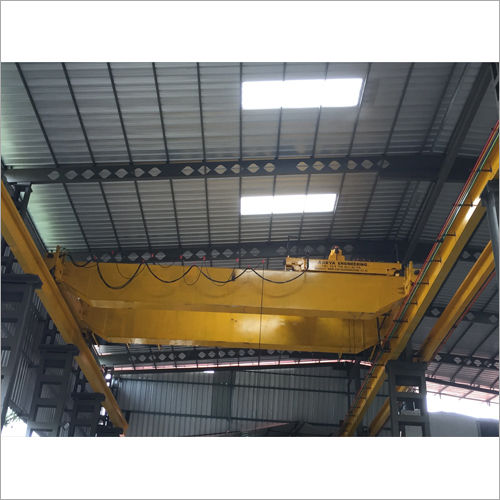

Industrial Girder EOT Crane

Price 500000.00 INR/ Set

Industrial Girder EOT Crane Specification

- Traveling Speed

- 20~40 m/min

- Brake

- Electromagnetic Brake

- Color

- Yellow

- Gearbox

- Precision Helical Gearbox

- Emergency Stop

- Available

- Electric Hoist

- High-performance electric hoist installed

- Application

- Industrial, Material Handling, Warehouse

- Usage

- Industrial

- Condition

- New

- Load Capacity

- up to 50 Ton

- Max. Lifting Height

- up to 30 m

- Max. Lifting Load

- 50 Ton

- Rated Lifting Moment

- Standard as per design

- Span

- up to 35 m

- Lifting Mechanism

- Wire Rope/Chain Hoist

- Lifting Speed

- 5~20 m/min

- Operating Mode

- Pendant/Remote/ Cabin Control

- Power Supply

- Three Phase AC

- Voltage

- 415 V / 380 V

- Frame Material

- High Strength Structural Steel

- Control System

- VFD/PLC-based advanced controls

- Design

- Double/Single Girder Type

- Working Temperature Range

- -20°C to 55°C

- Surface Treatment

- Epoxy/Polyurethane coated

- Noise Level

- Low noise operation

- Safety Features

- Overload Protection, Limit Switch, Anti-collision device

- Installation

- On-site installation support available

- Painting

- Corrosion Resistant Industrial Grade

- End Carriage

- Robust welded box type

- Duty Cycle

- Heavy-duty, Class II to IV

Industrial Girder EOT Crane Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cheque

- Delivery Time

- 2 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Industrial Girder EOT Crane

An Industrial Girder EOT Crane consists of one girder beam, with trolley and hoist running on the bottom flange of the single girder. The single girder crane has simple structure, low operating cost, quick installation and easy maintenance. It is used for light duty weight and short period work. It is most commonly preferred EOT crane that is usually used in load lifting and shifting. The Industrial Girder EOT Crane is very reliable and made for efficient performance.

Advanced Control Systems for Enhanced Productivity

The crane incorporates state-of-the-art Variable Frequency Drive (VFD) and Programmable Logic Controller (PLC) based controls. These technologies ensure smooth, precise handling and allow operators to customize performance for diverse applications. Options for pendant, remote, or cabin control provide exceptional operational flexibility and safety.

Uncompromising Safety and Durability

Designed with comprehensive safety features-overload protection, emergency stop, limit switches, and anti-collision devices-this crane prioritizes operator and asset protection. Its frame, built from high-strength steel and finished with industrial-grade corrosion-resistant paint, ensures durability even under heavy-duty cycles and in varied working temperatures.

Tailored Installation and Support

We provide expert on-site installation support, ensuring your crane is set up correctly and efficiently. Comprehensive after-sales service and support across India guarantee long-term reliability and operational continuity, making this solution perfect for distributors, manufacturers, and industrial users.

FAQ's of Industrial Girder EOT Crane:

Q: How is the Industrial Girder EOT Crane installed and does the company provide support?

A: The crane is installed on-site by our professional team, ensuring proper setup and alignment. We offer end-to-end installation support and guidance anywhere in India, making the process seamless for clients.Q: What safety features are included in this EOT crane for industrial operations?

A: Our crane features multiple safety mechanisms such as overload protection, emergency stop, limit switches, and anti-collision devices. These ensure maximum safety for operators and equipment during heavy-duty material handling.Q: When should I consider using a double girder versus a single girder design?

A: A double girder crane is ideal for heavier loads, larger spans (up to 35 m), or more demanding applications. Single girder cranes suit lighter loads and smaller facilities, providing a cost-effective yet reliable lifting solution.Q: Where is this crane best utilized and what industries can benefit from it?

A: The crane is designed for warehouses, factories, material handling facilities, and other industrial environments. Its robust design and safety features make it suitable for manufacturers, distributors, exporters, and service providers.Q: What is the typical process for maintaining the crane and ensuring its longevity?

A: Regular inspections, lubrication, and timely servicing of the mechanical and electrical components are recommended. Thanks to its precision helical gearbox, corrosion-resistant coating, and sturdy construction, the crane requires minimal maintenance.Q: How does the VFD/PLC control system benefit my operation?

A: The VFD/PLC-based control system enables precise control over lifting and traveling speeds, reducing mechanical stress and improving operational efficiency. It also offers smoother movements and customizable operating modes, enhancing safety and productivity during use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EOT Crane Category

Industrial EOT Crane

Price 100000.00 INR / Ton

Minimum Order Quantity : 1 Ton

Span : 10 m

Traveling Speed : 20 m/min

Color : Yellow

Usage : Industrial

Single Beam Overhead Crane

Price 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Span : 020 feet,2040 feet

Traveling Speed : 05 m/min m/m

Color : Yellow

Usage : Industrial

Eot Single Beam Cranes

Price 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Span : 2030 m

Traveling Speed : 05 m/min m/m

Color : Yellow

Usage : Industrial

Single Girder I Beam Eot Crane

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Span : 2030 m

Traveling Speed : 05 m/min m/m

Color : Yellow

Usage : Industrial

|

AARYA ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry