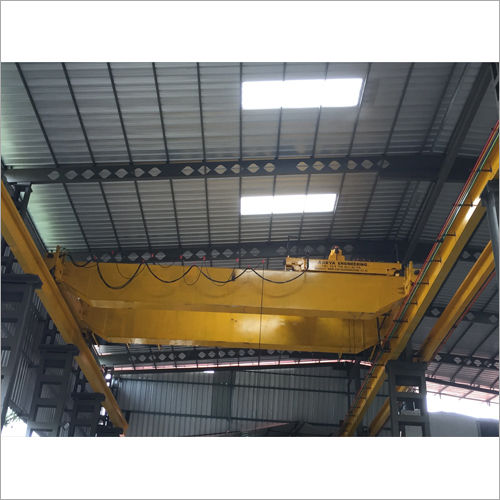

Single Girder EOT Crane

Price 600000 INR/ Unit

MOQ : 01 Set

Single Girder EOT Crane Specification

- Brake

- Electromagnetic

- Gearbox

- Helical Gear Type

- Application

- Factory, Warehouse, Workshop Material Handling

- Traveling Speed

- 20 m/min m/m

- Electric Hoist

- Included

- Color

- Yellow

- Condition

- New

- Load Capacity

- 1-20 Tons Tonne

- Max. Lifting Height

- 6-18 m Millimeter (mm)

- Max. Lifting Load

- 20 Tons Tonne

- Rated Lifting Moment

- As per design

- Span

- up to 30 m

- Lifting Mechanism

- Wire Rope Hoist

- Lifting Speed

- 5-8 m/min m/m

- Operating Mode

- Pendant/Radio Remote Control/Cabin

- Power Supply

- Electric

- Voltage

- 415V/3 Phase/50 Hz Volt (v)

Single Girder EOT Crane Trade Information

- Minimum Order Quantity

- 01 Set

- Supply Ability

- 10 Sets Per Month

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Single Girder EOT Crane

We are a professionally managed company with impressive track record for manufacturing a complete range of Single Girder EOT Crane. Our offered crane is made by our company is known for its strong designs and combine compactness with safety. We have made this Single Girder EOT Crane by using quality tested materials which is sourced from the trustworthy vendors of the industry. Our customers can avail from us these cranes in various specifications according to their need and requirements.

Efficient & Smooth Operation

This EOT crane stands out for its inverter (VFD)-driven controls that provide smooth acceleration and deceleration, minimizing jerks and enhancing both safety and precision during handling. The robust helical gearbox further ensures quiet and efficient power transmission, making it ideal for continuous industrial use.

Rugged Design for Versatile Applications

Fabricated from heavy-duty steel and treated with anti-corrosive epoxy enamel paint, the crane provides lasting durability in challenging environments. Whether you're using it indoors or outdoors, its resilient components and IP55 electricals make maintenance effortless, supporting operations in temperatures from -10C to +60C.

Built-In Safety & User Control

Incorporating essential safety features such as over-hoisting/over-lowering limit switches, electromagnetic braking, and an emergency stop, the crane ensures operator wellbeing and equipment protection. Multiple control options-including pendant, radio remote, or cabin-allow users to choose the ideal mode for their working environment.

FAQ's of Single Girder EOT Crane:

Q: How does the inverter (VFD) panel enhance crane operation?

A: The inverter (VFD) control system ensures smooth and precise movement by regulating the crane's speed, reducing mechanical stress and load sway. This not only boosts operational safety but also improves load handling accuracy during lifting and traversing processes.Q: What is the typical usage of this Single Girder EOT Crane?

A: This crane is widely used for material handling in factories, warehouses, and workshops. Its sturdy design enables efficient transportation of loads ranging from 1 to 20 tons, making it a reliable choice for various industrial applications.Q: When should I choose a Class II/III duty crane as per IS: 3177?

A: Select a Class II/III duty crane if you require moderate to heavy operation, such as frequent lifts and varied loads, but without extreme usage. These classes align with IS: 3177 standards for general manufacturing, storage, and assembly environments.Q: Where can this crane be installed?

A: The crane is suitable for both indoor and outdoor settings, thanks to its IP55-rated electricals and anti-corrosive epoxy enamel paint. It operates reliably in environments ranging from -10C to +60C, making it adaptable for diverse industrial sites.Q: What is the process for operating the crane?

A: The crane can be operated via pendant control, radio remote, or cabin mode, depending on user preference. Safety mechanisms like emergency stop and limit switches are built-in, which provides operators with comprehensive and responsive control over all crane functions.Q: What are the benefits of the included wire rope hoist and electromagnetic brake?

A: The wire rope hoist offers reliable lifting with minimal wear, accommodating heights from 6 to 18 meters. The electromagnetic brake ensures immediate and secure stopping, providing an extra layer of safety during load handling.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in EOT Crane Category

Double Girder EOT Crane

Price 500000.00 INR / Set

Minimum Order Quantity : 1 Set

Color : GOLDEN YELLOW

Span : 5 MTR TO 35 MTR

Usage : INDUSTRIAL

Condition : New

Heavy Duty Cranes

Price 1000000 INR / Number

Minimum Order Quantity : 1 Number

Color : Yellow

Span : 3 TO 40 MTR

Usage : INDUSTRIAL

Condition : New

Industrial EOT Crane

Price 100000.00 INR / Ton

Minimum Order Quantity : 1 Ton

Color : Yellow

Span : 10 m

Usage : Industrial

Condition : New

Single Beam EOT Crane

Price 500000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Yellow

Span : 1020 m

Usage : used primarily in factories, warehouses, and workshops for handling light to medium loads

Condition : New

|

AARYA ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry